Rojo Alicante & Bianco Dolomite Marble 3" x 12" Picket Mosaic – A Striking Fusion of Warmth and Elegance

Rich Spanish Red Meets Timeless White in a Bold Geometric Design

The Rojo Alicante & Bianco Dolomite Marble 3" x 12" Picket Mosaic is a stunning combination of deep red Spanish marble and crisp white dolomite, creating a warm yet sophisticated contrast. This premium natural stone mosaic blends Mediterranean vibrancy with timeless elegance, making it a perfect choice for kitchen backsplashes, luxurious bathrooms, feature walls, and decorative borders.

The elongated picket pattern adds architectural movement and modern geometry, giving interiors a refined and stylish touch. Whether incorporated into classic or contemporary designs, this polished marble mosaic ensures a high-end, designer-inspired finish.

Premium Natural Stone Composition

✔️ Rojo Alicante Marble – A deep, fiery red marble with soft white veining, sourced from Spain, adding warmth and richness to any space.

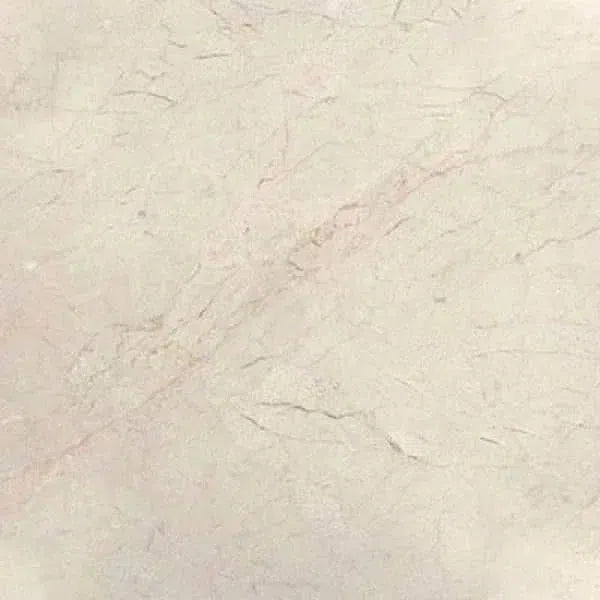

✔️ Bianco Dolomite Marble – A bright white dolomite marble with subtle gray undertones, offering elegance and balance.

✔️ Polished Finish – Highlights the natural color contrast and veining while creating a luxurious, glossy surface.

Each hand-selected tile showcases unique natural variations, ensuring an authentic and high-end look in every installation.

Size & Format

✔️ 3" x 12" Picket Shape – A modern yet timeless geometric layout that enhances depth and movement.

✔️ Polished Surface – Enhances the natural beauty of the marble while reflecting light beautifully.

✔️ Mesh-backed for Easy Installation – Provides precise alignment for a seamless, professional finish.

The elongated picket pattern is a sophisticated alternative to subway tiles, bringing refinement and artistry to interior spaces.

Perfect for Various Applications

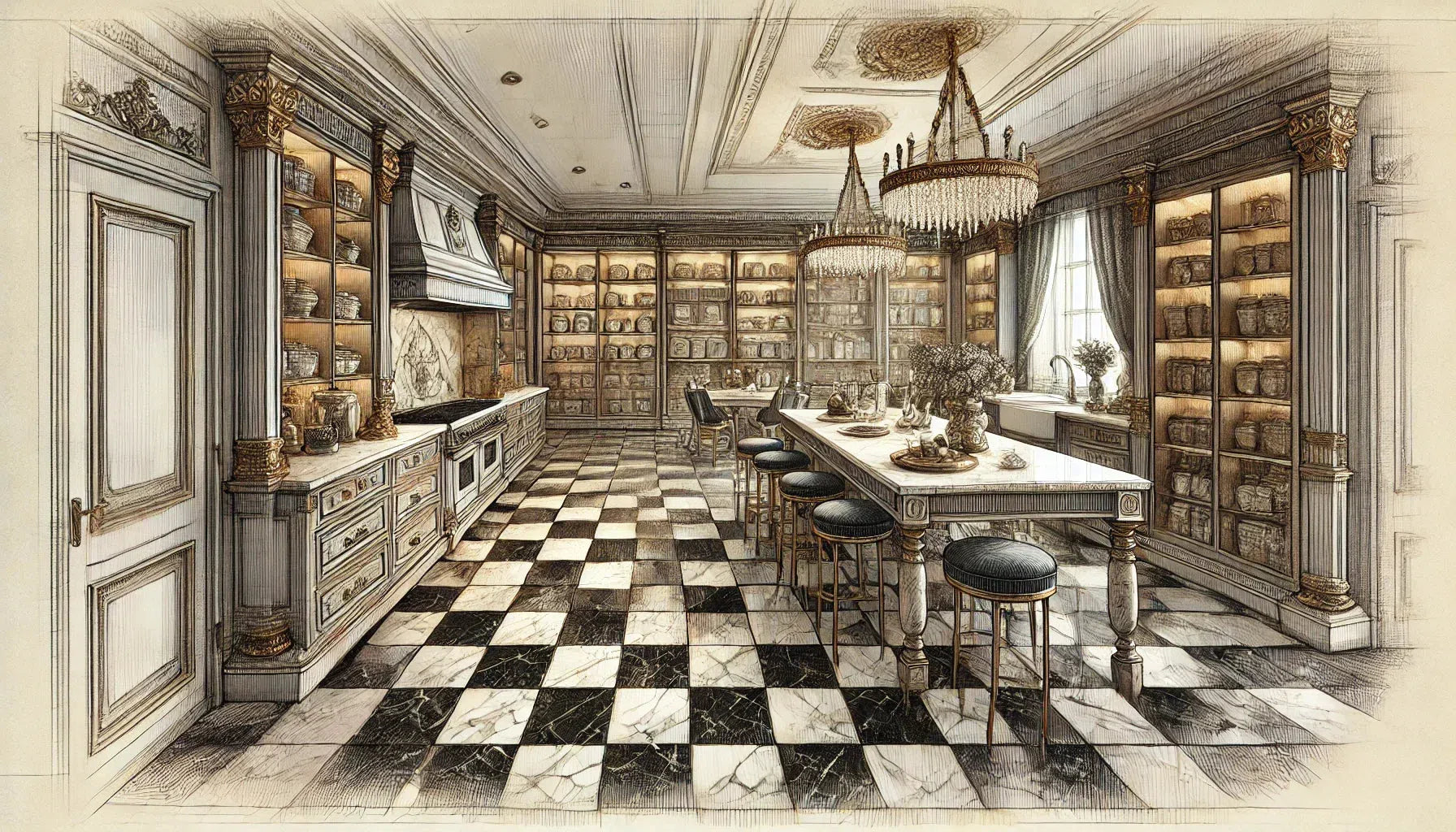

✔️ Kitchen Backsplashes – Adds a warm yet luxurious contrast to countertops and cabinetry.

✔️ Bathroom & Shower Walls – Elevates bathrooms with a unique blend of bold color and timeless elegance.

✔️ Feature Walls & Entryways – Creates a striking focal point in sophisticated spaces.

✔️ Decorative Borders & Trim – Enhances floors and walls with a refined, high-end detail.

This versatile red-and-white marble mosaic complements neutral tones, gold accents, and contemporary furnishings, making it an exquisite choice for high-end interiors.

Aesthetic Appeal & Design Flexibility

✔️ Warm Red & Crisp White Contrast – A dynamic yet balanced color combination.

✔️ Luxury Architectural Accent – The elongated picket format creates depth and movement.

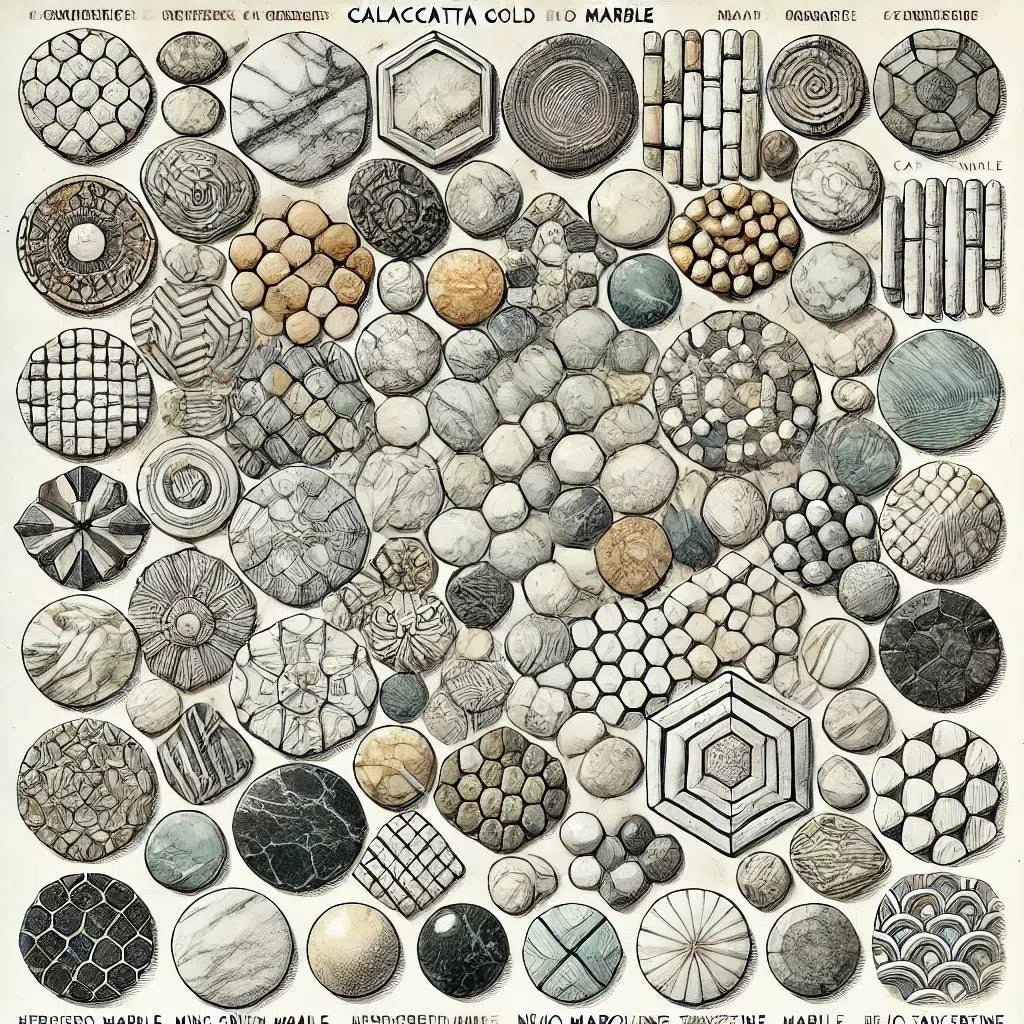

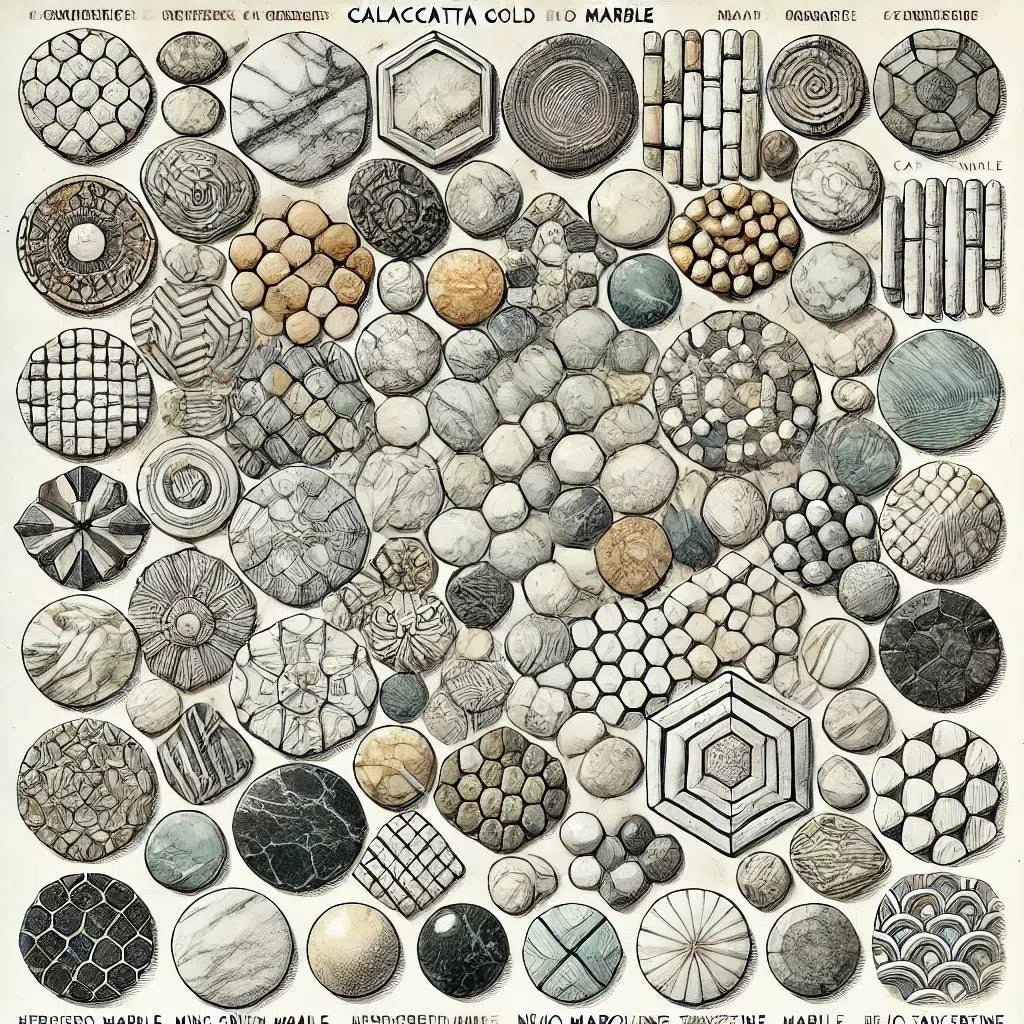

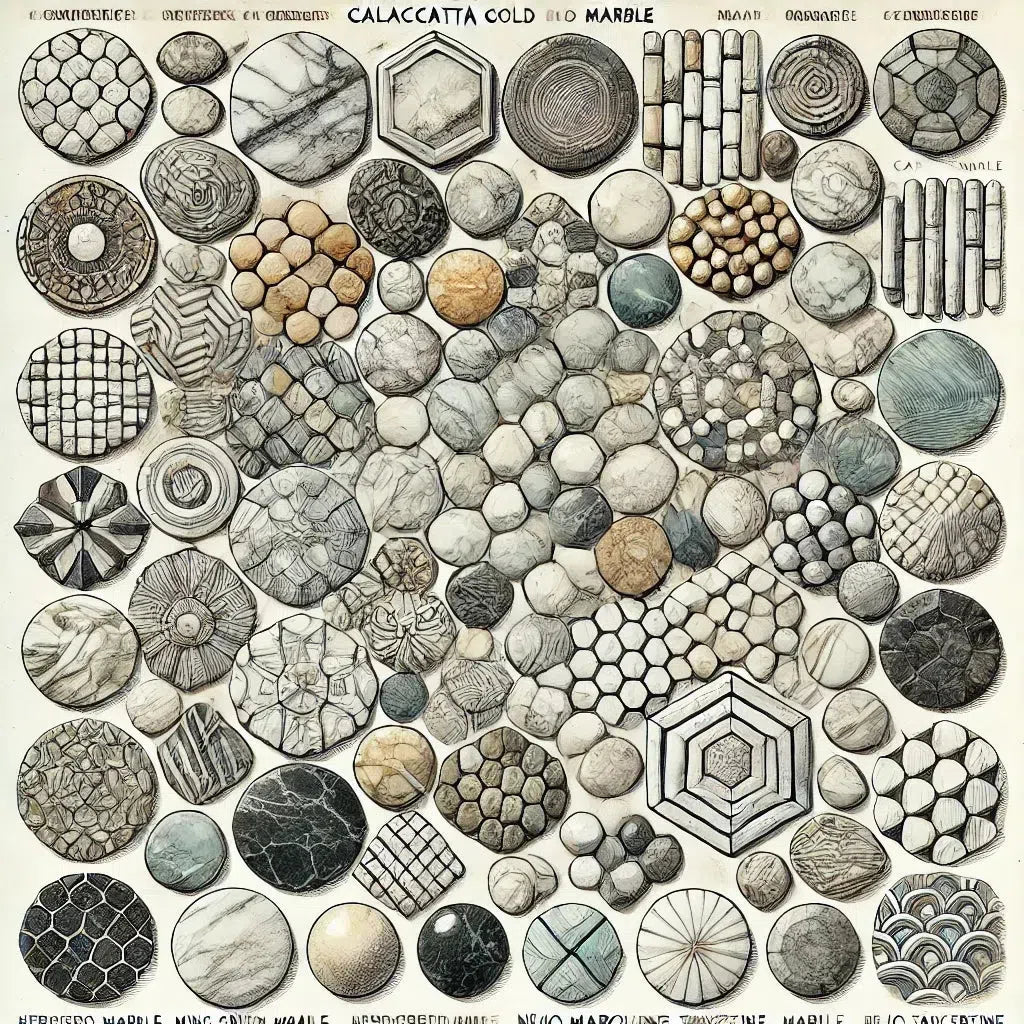

✔️ Pairs Beautifully with Other Natural Stones – Complements Carrara, Calacatta Gold, and Nero Marquina Marble for an elevated contrast.

From Mediterranean-inspired spaces to modern minimalist interiors, this Rojo Alicante & Bianco Dolomite picket mosaic enhances any setting with warmth, vibrancy, and timeless elegance.

Durability & Easy Maintenance

✔️ 100% Natural Marble – A premium, long-lasting natural stone.

✔️ Polished Finish – Provides a smooth, easy-to-clean surface.

✔️ Sealing Recommended – Protects against moisture, stains, and daily wear.

With proper care and sealing, this stunning picket mosaic maintains its luxurious appeal for years.

Why Choose Rojo Alicante & Bianco Dolomite Picket Mosaic?

✔️ Authentic Spanish & Italian Marble – A unique and luxurious stone combination.

✔️ Versatile & High-End Design – Ideal for modern and classic interiors.

✔️ Premium Quality & Timeless Durability – A statement piece in natural stone elegance.

Upgrade your space with the Rojo Alicante & Bianco Dolomite Marble 3" x 12" Picket Mosaic, where Mediterranean warmth meets contemporary refinement, delivering a bold and sophisticated design statement.

Product Size : Rojo Alicante & Bianco Dolomite Marble 3" X 12" Picket Mosaic

Product Thickness : 3/8"

Product Coverage : (sq.ft./pcs) 0.75 sqft / 3 pcs

Material : Marble

Color : Gray , Blue , White

Finish : Polished / Honed

Edge : Straight

Origin : Raw Material from Italy Hand Made in CA

All Size-Dimensions Are Nominal

Our custom mosaics are handcrafted, which may result in slight imperfections. These variations are a natural part of the artisanal process and add to the uniqueness of each piece. Once installed and grouted, these minor inconsistencies will blend seamlessly, ensuring a flawless and cohesive finish.

Material Inspection and Installation Guidelines

Material Inspection

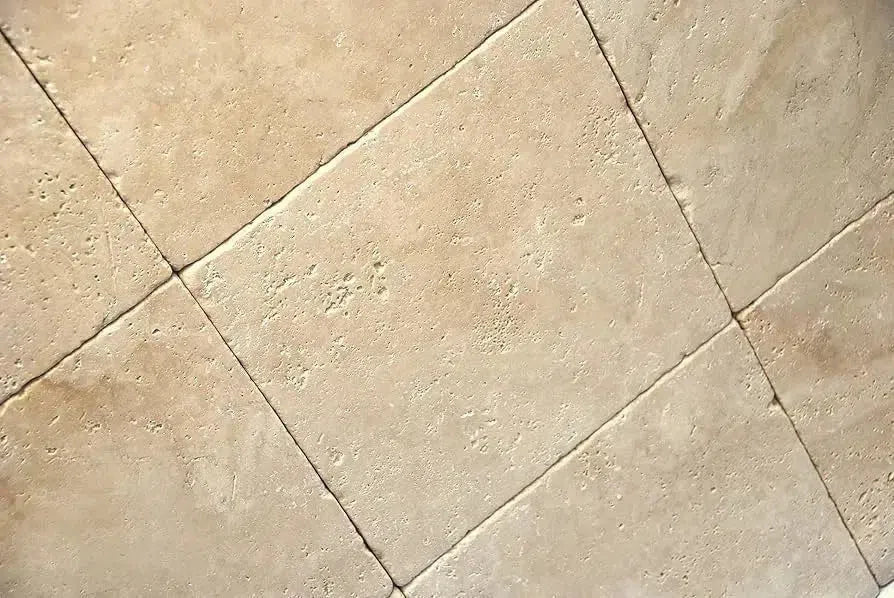

Before installation, carefully inspect all goods for any damage or defects such as chipped edges or broken pieces. Natural stone surfaces, including marble and travertine, will have naturally occurring variations in color, pattern, texture, and veining that may differ from what was pictured. No adjustments or services can be provided once installation has begun.

Substrate Preparation

To ensure a proper installation, follow these substrate guidelines:

• Surface Condition: The substrate must be clean, flat, and free of contaminants, including curing compounds. It should also be free of cracks.

• Waterproofing: In wet areas, waterproof the substrate following the manufacturer's recommendation for a waterproofing and crack prevention membrane compatible with your setting material.

• Expansion Joints: Install expansion joints at all changes in plane in the tile work and where tile abuts restraining surfaces. Use silicone caulking sealant instead of grout in all corner joints.

Installation

Dry-Fitting

• Pattern Planning: Dry-fit your pattern before starting installation. Visualize the installation and plan the placement of pieces, especially with tiles that have a lot of variation.

Mortar Application

• Thin-Set Mortar: Use white thin-set mortar to avoid affecting the tile color. For faster installation, use a rapid curing thin-set mortar.

• Application:

◦ Apply adhesive to an area that can be covered within 10-15 minutes.

◦ Grout joints should be a minimum of 1/16” and not butt set.

◦ Smooth down the ridges using the flat side of the trowel before fixing the tiles in the mortar bed.

◦ For our ceramic material, use a 3/16" or 1/4" square notch trowel. For other tiles, a 9" trowel with a 1/8" square notch is recommended.

Grouting

• Non-Sanded Grout: Use non-sanded grout for ceramic tiles to prevent scratching. Test a small area before grouting to ensure the stone surface does not scratch.

• Packing Grout Joints: Pack grout joints fully, avoiding pits or voids. Clean excess grout as you work, and do not let it harden completely.

• Cleaning: Never use acids to clean grout haze. Use a damp sponge for final cleaning and smoothing grout joints.

• Grout Release: Apply grout release before grouting to facilitate cleaning and protect against staining from contrasting color grouts.

Cutting

• Tools: Use a wet-saw with a new, continuous rim diamond blade designed for cutting ceramic tile for the best results.

Cleaning

General Cleaning

• Porcelain Tile: Clean with a damp sponge mop and a solution of 1/4 cup white vinegar to every 2 gallons of water. Sweep or vacuum regularly.

Unpolished Surfaces

• Sweeping: Use a soft-bristle broom and sweep in two directions: along the grain and diagonally to dislodge dust and debris.

• Cleaning Solution: Saturate the tile with a neutral cleaning solution like vinegar and hot water, let it sit for 5–10 minutes, then scrub with a brush using the two-direction method.

• Rinsing: Rinse with clean water to remove the cleaning solution.

High Traffic Areas

• Clean at least once per day and wet mop regularly.

Reminders

• Avoid Certain Cleaners: Do not use ammonia, bleach, or acid-based cleaners, as they may alter grout color. Avoid wax, oil-based, abrasive cleaners, sealants, and agents with dyes or colors.

• Steel Wool: Do not use steel wool pads, as leftover particles may rust.

• Entrance Rugs: Place rugs at entrances to minimize dirt and grit from being tracked onto the tile flooring from outdoors.

By following these guidelines, you will ensure the successful and lasting installation of your natural stone surfaces.

The Waste Factor

How Much Do I Need to Order?

The best practice is to order at least 10-30% more than your project requirements to account for potential issues, waste due to cutting material, and other potential breakage during installation.

When installing natural stone, understanding the waste factor is crucial. The waste factor refers to the amount of stone that will be cut, trimmed, or otherwise discarded during the installation process. The waste factor varies depending on how tightly the stones are fitted; tighter joints require more trimming and thus produce more waste.

Waste Factor Considerations

• Project Size: Larger projects might have a slightly lower percentage of waste due to more efficient use of materials.

• Joint Tightness: Tighter joints increase the waste factor due to more precise trimming.

• Stone Variations: Natural stones have variations in color and texture, necessitating extra materials to ensure consistency across the installation.

Example Calculation

For a project area of 1,000 square feet with an expected waste factor of 10% to 30%, you would need to purchase between 1,100 and 1,300 square feet of stone.

Tips for Managing Waste

1. Mock-Up: Create a small mock-up to better estimate your specific waste factor before ordering materials.

2. Order Extra: Always order extra materials for future repairs or additions, as natural stone batches can vary.

3. Efficient Cutting: Plan cuts carefully to minimize waste and use off-cuts in less visible areas.

By accurately calculating the waste factor and ordering extra material, you can ensure a smoother installation process and a consistent appearance of your natural stone veneer.

Installation Tips

Installing natural stone flooring can be a rewarding project, giving your home a luxurious and timeless look. Here's a step-by-step guide to help you through the process:

Materials and Tools Needed:

• Natural stone tiles (marble, granite, slate, etc.)

• Tile adhesive (thin-set mortar)

• Grout

• Tile spacers

• Notched trowel

• Level

• Tape measure

• Tile cutter or wet saw

• Rubber mallet

• Sponge and bucket

• Grout float

• Sealer (specific to your type of stone)

• Safety equipment (gloves, goggles, knee pads)

Step-by-Step Guide:

1. Preparation:

• Measure the Area: Calculate the square footage of the area where you plan to install the tiles.

• Prepare the Subfloor: Ensure that the subfloor is clean, dry, and level. If necessary, apply a self-leveling compound.

• Acclimate the Tiles: Let the stone tiles sit in the installation area for a couple of days to acclimate to the room temperature and humidity.

2. Layout Planning:

• Dry Lay the Tiles: Lay out the tiles without adhesive to plan the pattern and placement. Start from the center and work your way out to ensure an even layout.

• Mark Guidelines: Use a chalk line to mark the center of the room and create reference lines for laying the tiles.

3. Applying Adhesive:

• Mix the Thin-set Mortar: Follow the manufacturer's instructions to mix the mortar.

• Spread the Mortar: Using the notched trowel, spread the thin-set mortar on a small section of the subfloor. Hold the trowel at a 45-degree angle to create ridges in the mortar.

4. Laying the Tiles:

• Place the Tiles: Press the tiles into the mortar, twisting them slightly to ensure a good bond. Use tile spacers to maintain consistent gaps between the tiles.

• Check for Level: Regularly check that the tiles are level and adjust as necessary using the rubber mallet.

5. Cutting Tiles:

• Measure and Mark: Measure the tiles that need to be cut to fit along the edges and mark them.

• Cut the Tiles: Use a tile cutter or wet saw to cut the tiles to the required size.

6. Grouting:

• Allow Adhesive to Cure: Let the adhesive dry for at least 24 hours or as recommended by the manufacturer.

• Mix the Grout: Mix the grout according to the instructions.

• Apply the Grout: Using a grout float, apply the grout diagonally across the tiles to fill the gaps. Remove excess grout with the float.

• Clean the Tiles: Use a damp sponge to wipe off excess grout from the tile surfaces. Rinse the sponge frequently and be careful not to remove grout from the joints.

7. Sealing:

• Allow Grout to Cure: Let the grout cure for the recommended time, usually 48-72 hours.

• Seal the Tiles: Apply a stone sealer to protect the tiles from stains and moisture. Follow the manufacturer's instructions for application and curing times.

8. Final Touches:

• Clean the Floor: After the sealer has dried, give the floor a final cleaning to remove any residue.

• Inspect the Installation: Check the tiles and grout lines for any imperfections and make any necessary repairs.

Tips:

• Always wear safety equipment when cutting tiles.

• Follow the manufacturer's instructions for all materials used.

• Work in small sections to prevent the adhesive from drying out before the tiles are laid.

• Regularly clean your tools to prevent the mortar and grout from hardening on them.

This guide should help you install natural stone flooring successfully. If you have any specific questions or encounter any issues during the installation, feel free to ask!

California Proposition 65

WARNING: Products sold at Surfaces Galore contain chemicals, including stone dust, which are known to the State of California to cause cancer, birth defects or other reproductive harm.

Disclaimer: Surfaces Galore provides information to give customers an overview of the process from choosing to installation of our natural stone surfaces. However, we are not responsible for any mistakes, problems, or issues that may arise. All responsibility for the selection, installation, and any associated outcomes rests solely with the customers.

Best Selling Marble Collections

Best Selling Marble Collections

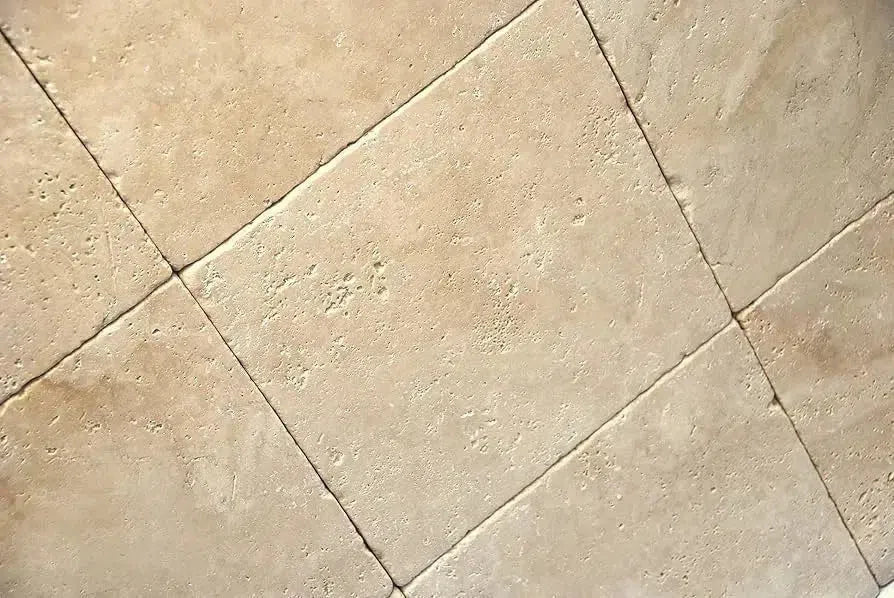

Best Selling Travertine Collections

Best Selling Travertine Collections

Checkerboard

Checkerboard

Patterned Tile

Patterned Tile

Shop By Material

Shop By Material

Shop By Name

Shop By Name

Absolute Black Granite

Absolute Black Granite

Arabescato (Italian) Marble

Arabescato (Italian) Marble

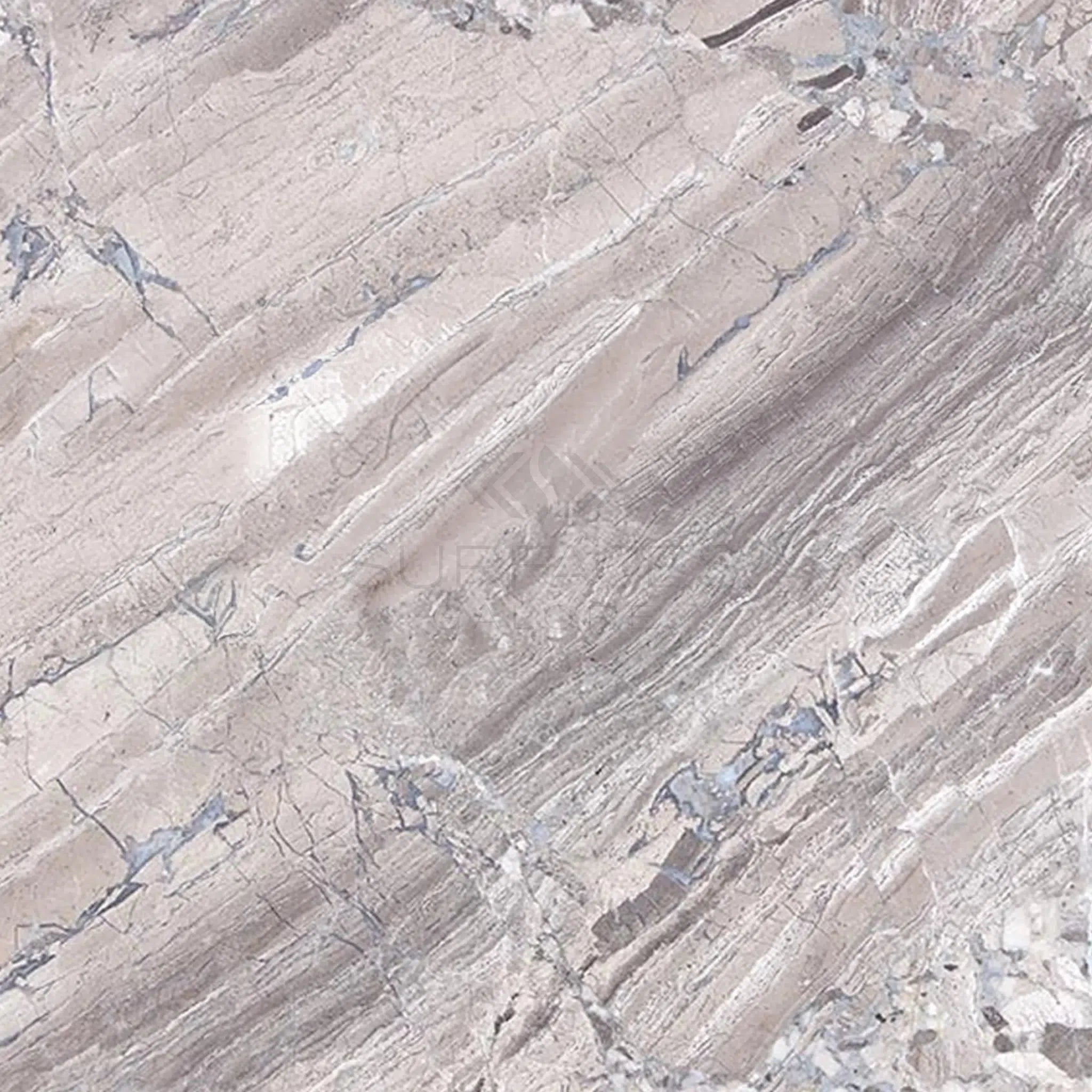

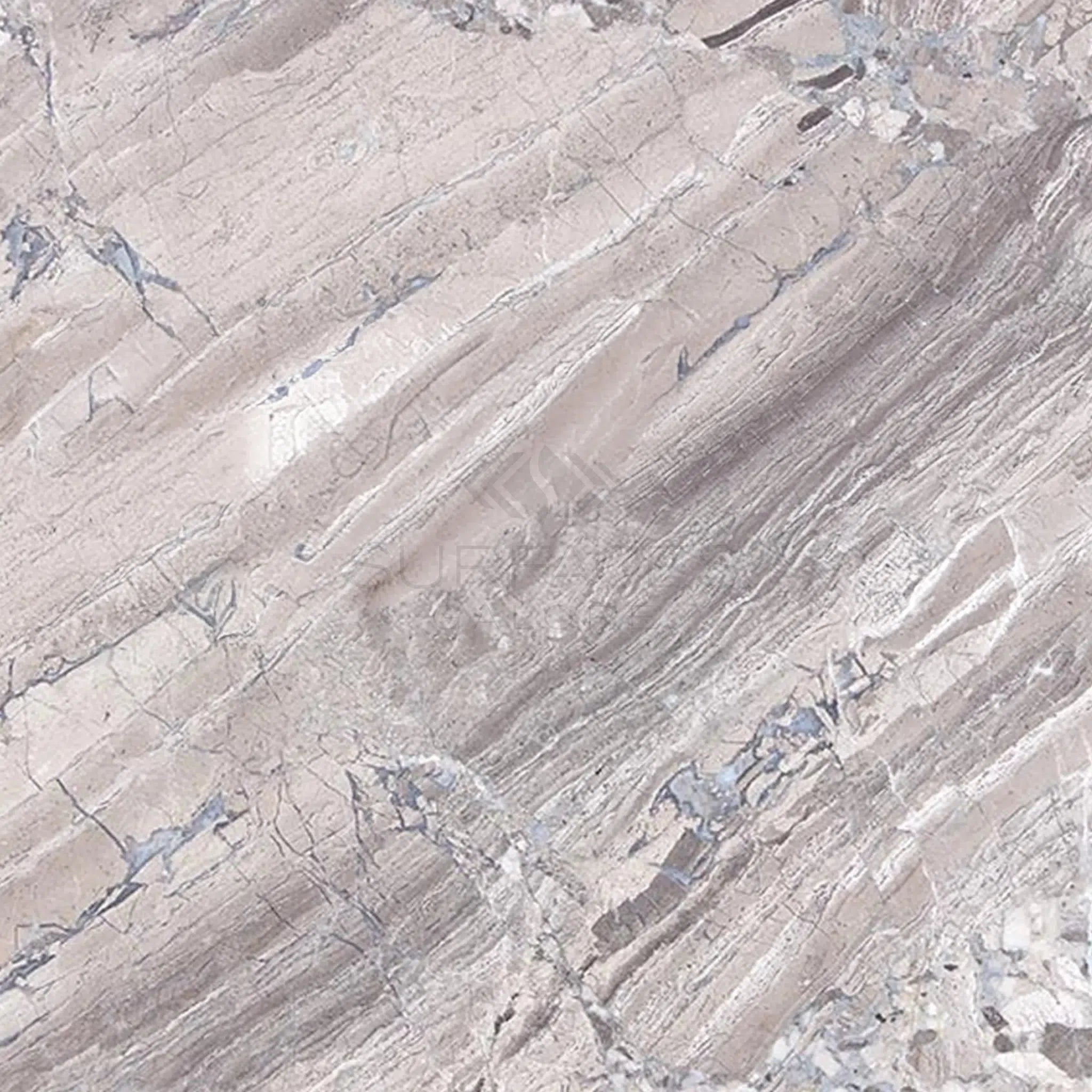

Atlantic Gray Marble

Atlantic Gray Marble

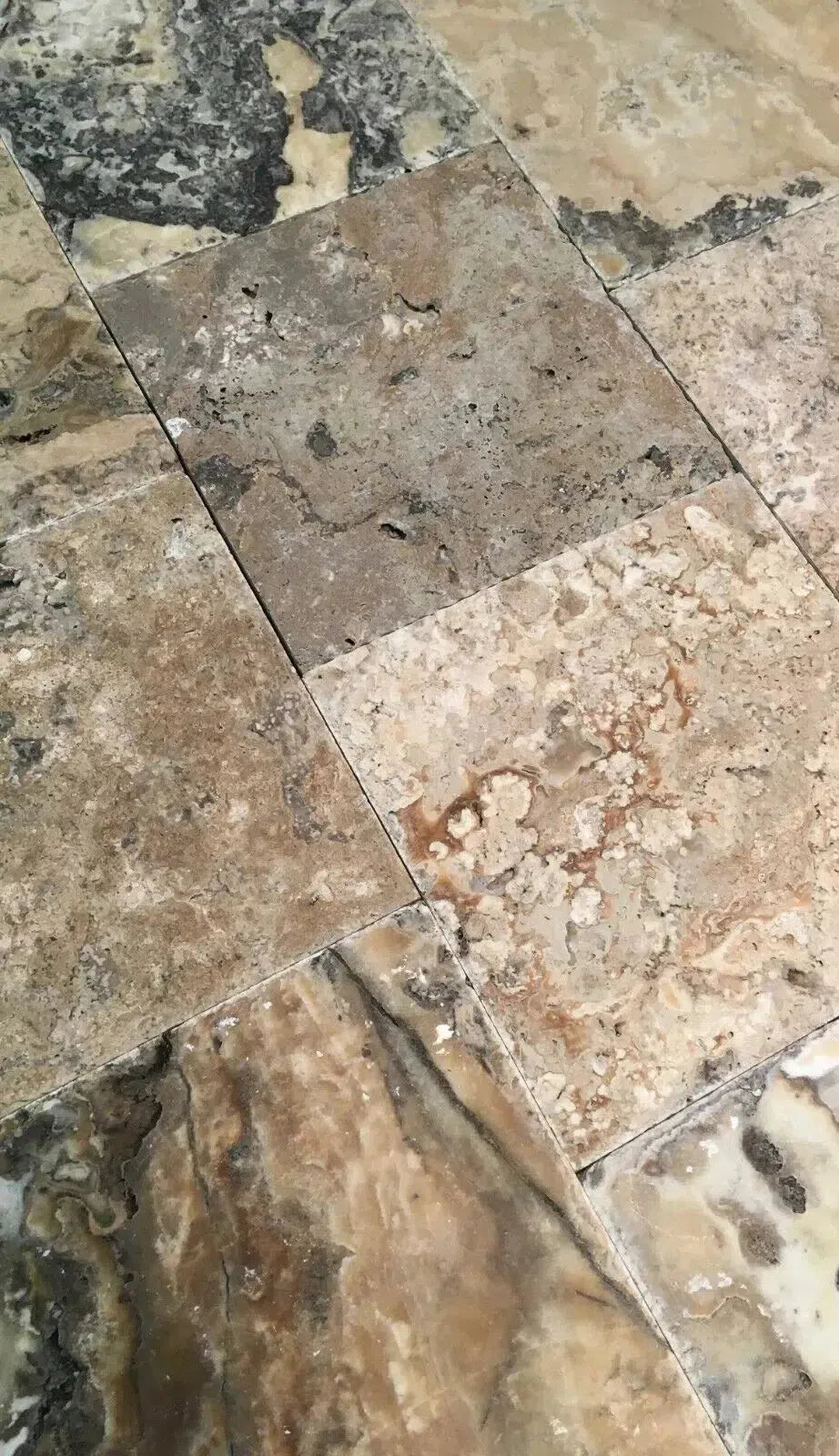

Antico Onyx Travertine

Antico Onyx Travertine

Bardiglio (Italian) Marble

Bardiglio (Italian) Marble

Bianco Congelato Dolomite

Bianco Congelato Dolomite

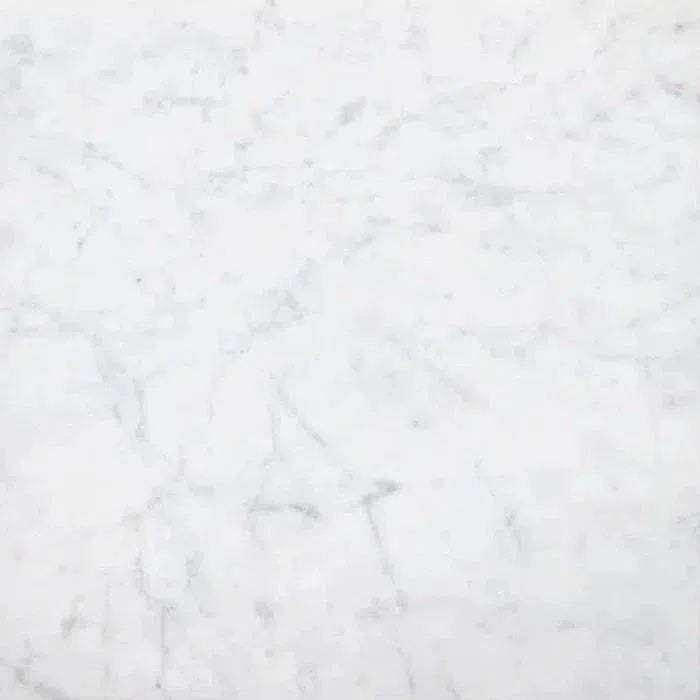

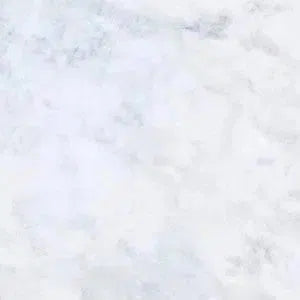

Bianco Dolomite (White Dolomite) Marble

Bianco Dolomite (White Dolomite) Marble

Bianco Venatino (Bianco Mare) Marble

Bianco Venatino (Bianco Mare) Marble

Calacatta Gold Marble

Calacatta Gold Marble

Calacatta Oliva Marble

Calacatta Oliva Marble

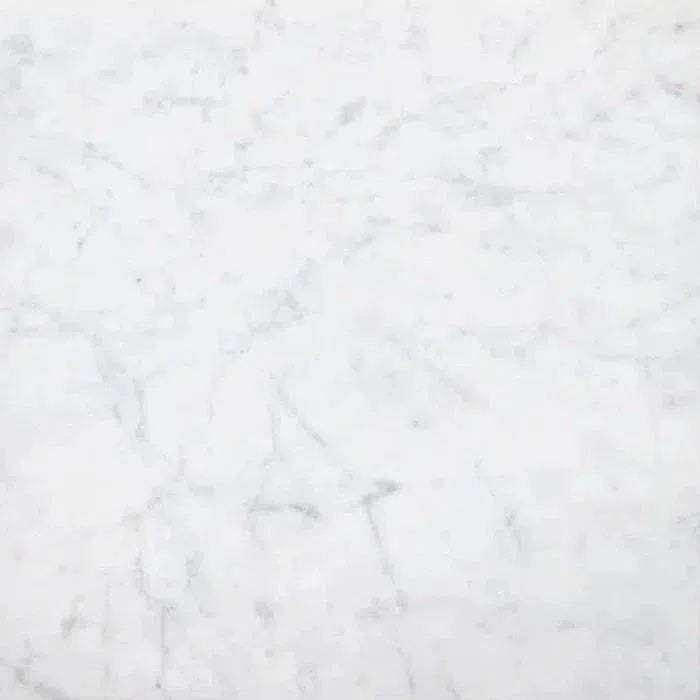

Carrara White Marble

Carrara White Marble

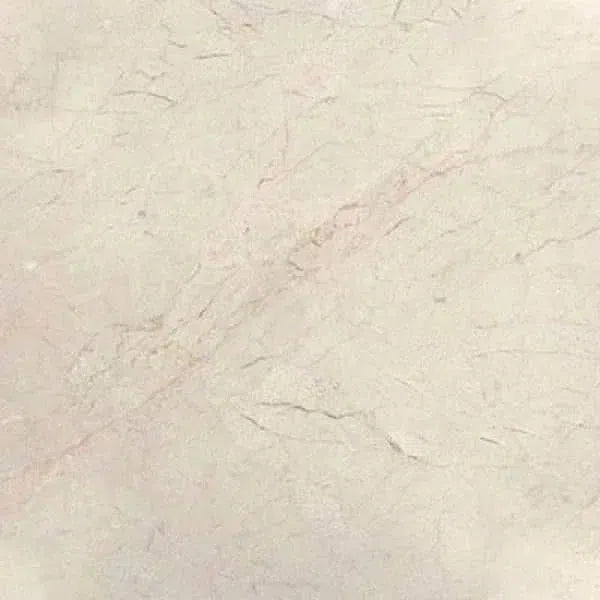

Crema Marfil Marble

Crema Marfil Marble

Cappuccino Marble

Cappuccino Marble

Custom-Made Mosaic

Custom-Made Mosaic

Diano Royal (Queen Beige) Marble

Diano Royal (Queen Beige) Marble

Durango Cream Traverine

Durango Cream Traverine

Emperador Dark Marble

Emperador Dark Marble

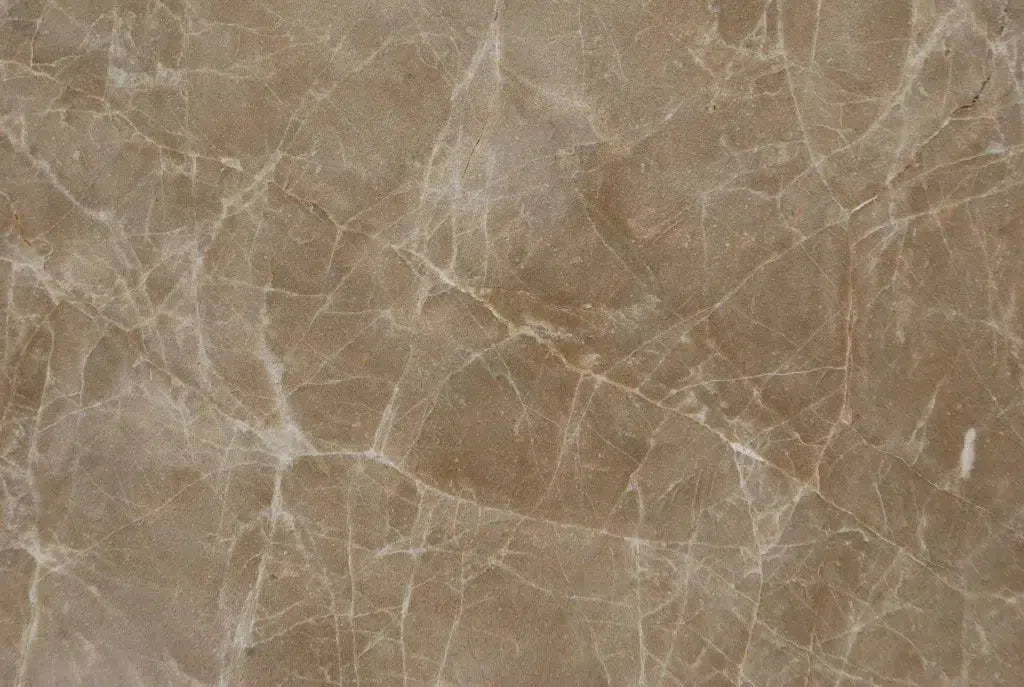

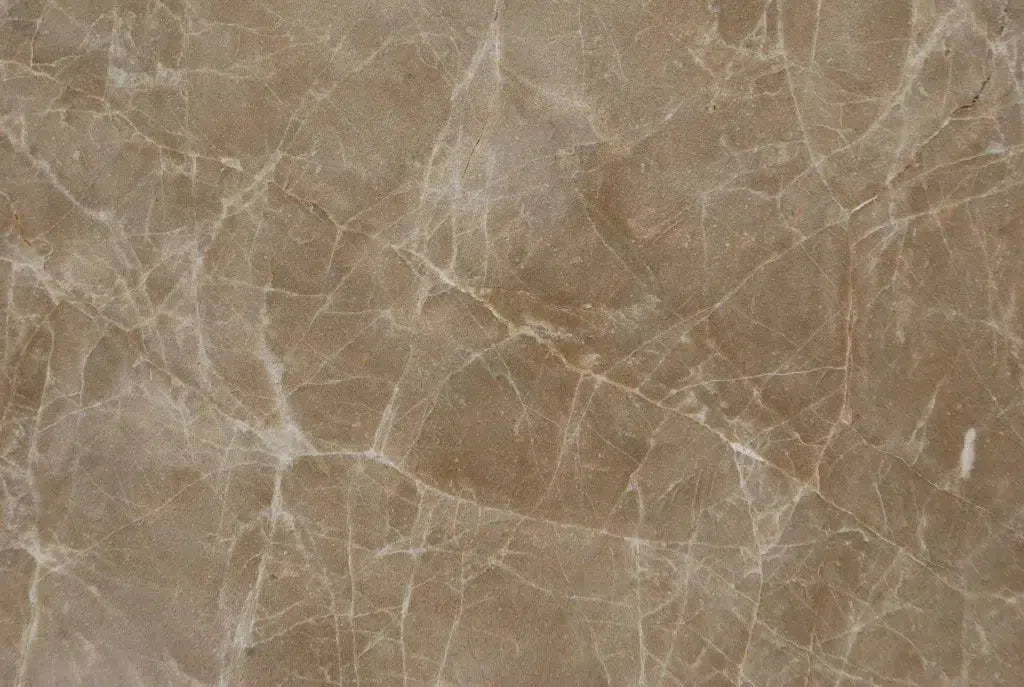

Emperador Light Marble

Emperador Light Marble

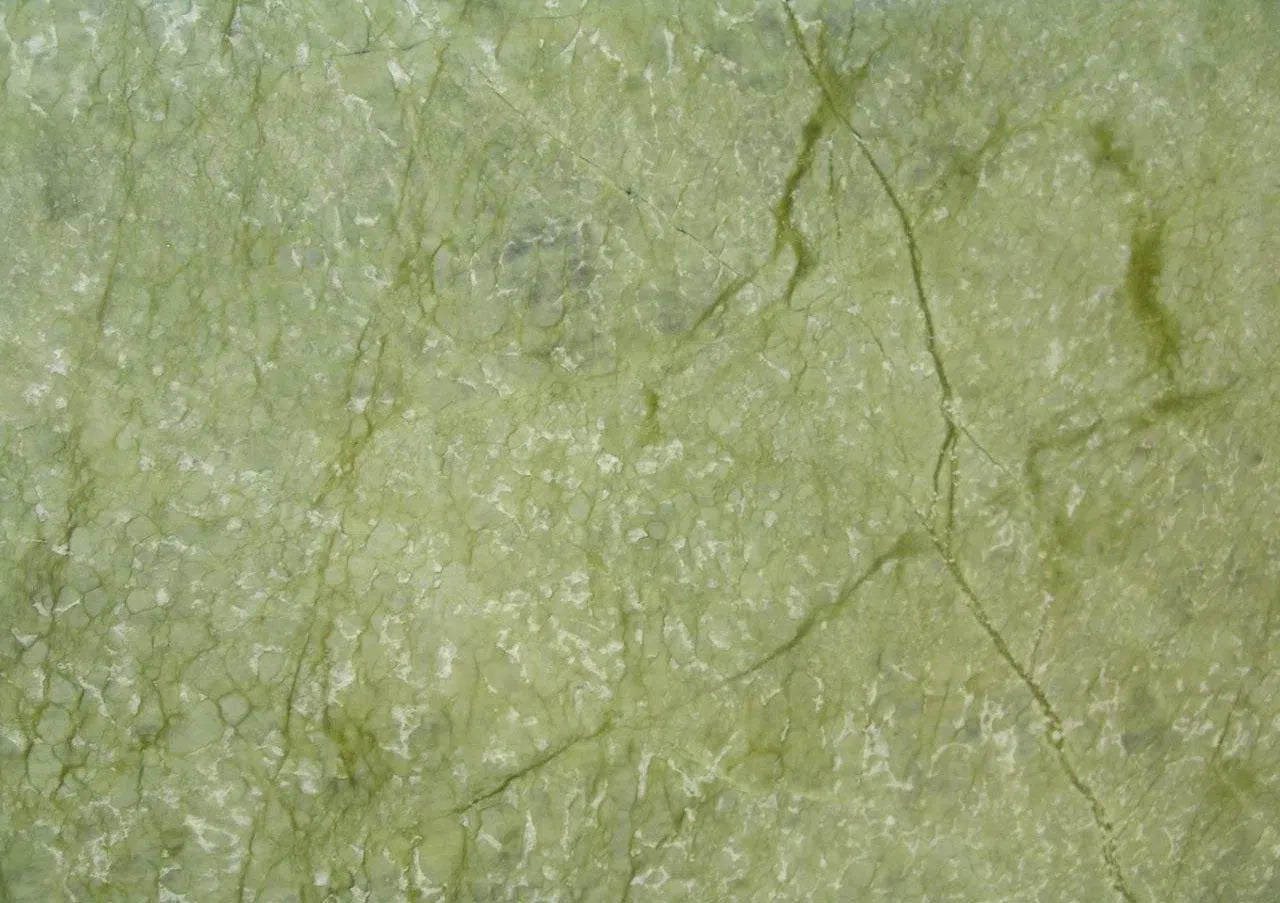

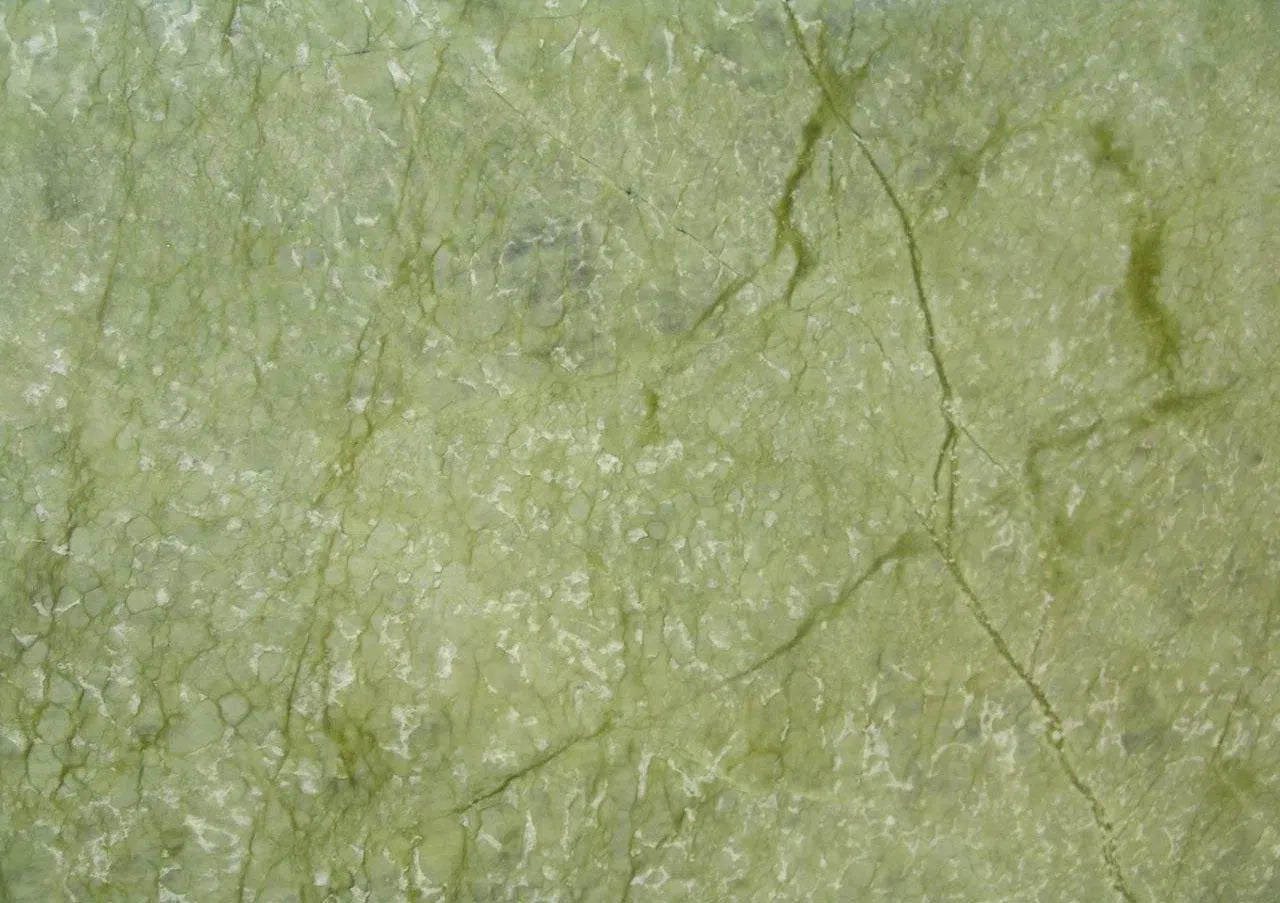

Empress Green Marble

Empress Green Marble

Exotic Vein-Cut Travertine

Exotic Vein-Cut Travertine

Gold/Yellow Travertine

Gold/Yellow Travertine

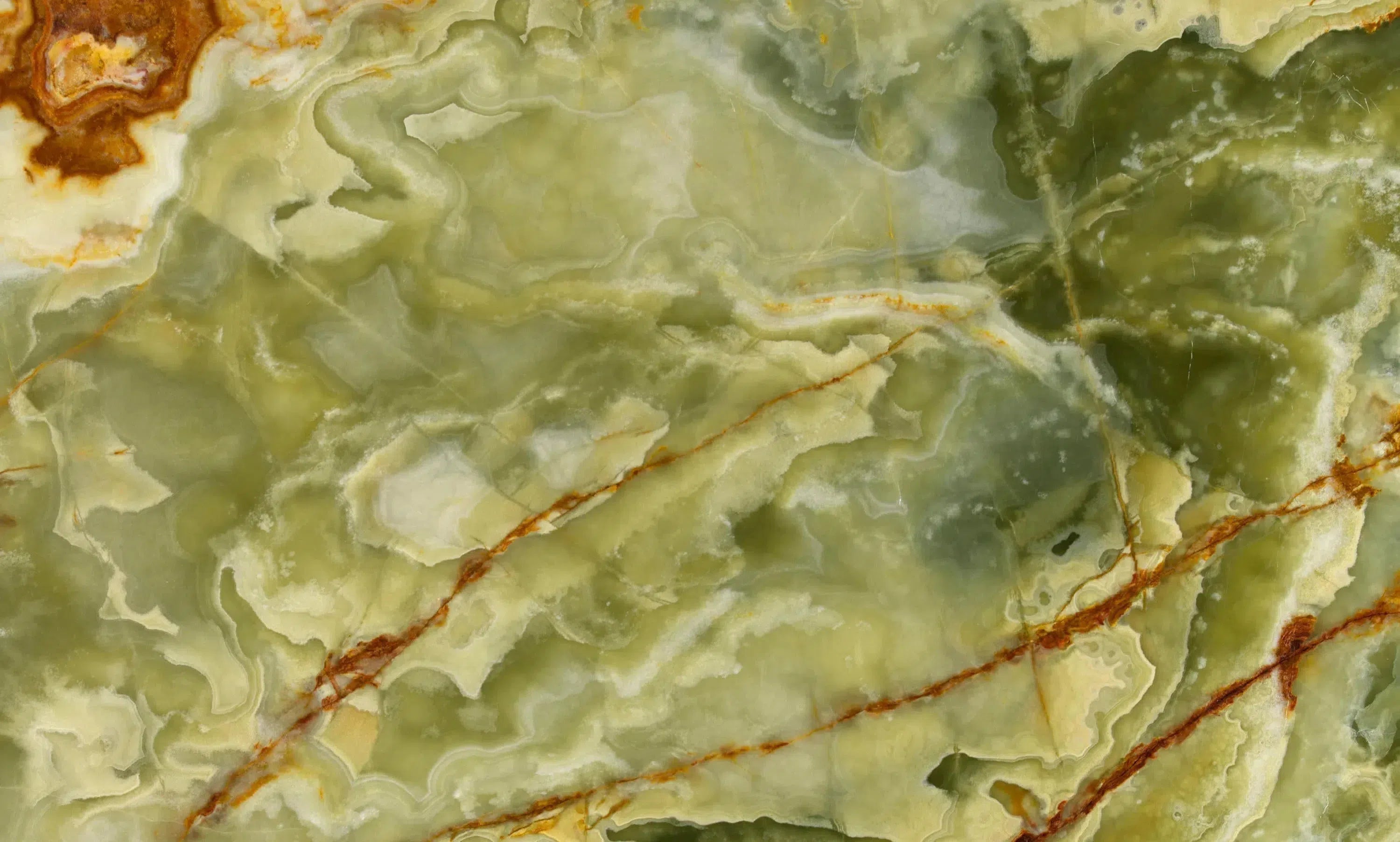

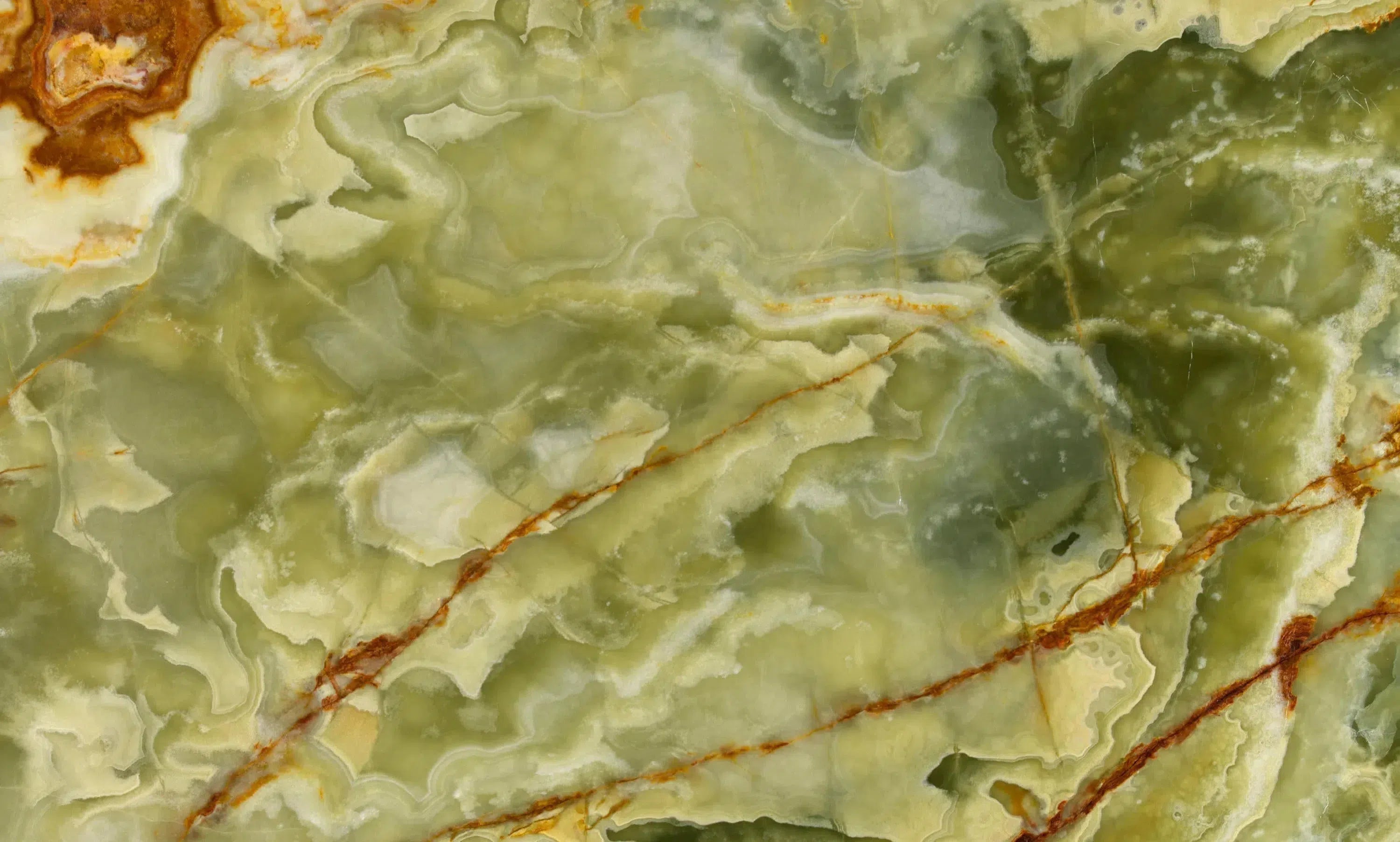

Green Onyx Marble

Green Onyx Marble

Haisa Light (White Wood) Limestone

Haisa Light (White Wood) Limestone

Honey Onyx Marble

Honey Onyx Marble

Ivory (Light) Travertine

Ivory (Light) Travertine

La Travonya Travertine

La Travonya Travertine

Malibu Travertine

Malibu Travertine

Ming Green Marble

Ming Green Marble

Mink (Equator) Marble

Mink (Equator) Marble

Mixed (Ivory-Noce-Gold) Travertine

Mixed (Ivory-Noce-Gold) Travertine

Nero Marquina/Black Marble

Nero Marquina/Black Marble

Noce Exotic (Vein Cut) Travertine

Noce Exotic (Vein Cut) Travertine

Noce Travertine

Noce Travertine

Oriental White Marble

Oriental White Marble

Pierre Bleue (Pierre Blue) Marble

Pierre Bleue (Pierre Blue) Marble

Philadelphia Travertine

Philadelphia Travertine

Rosso Levanto Marble

Rosso Levanto Marble

Rojo Alicante Marble

Rojo Alicante Marble

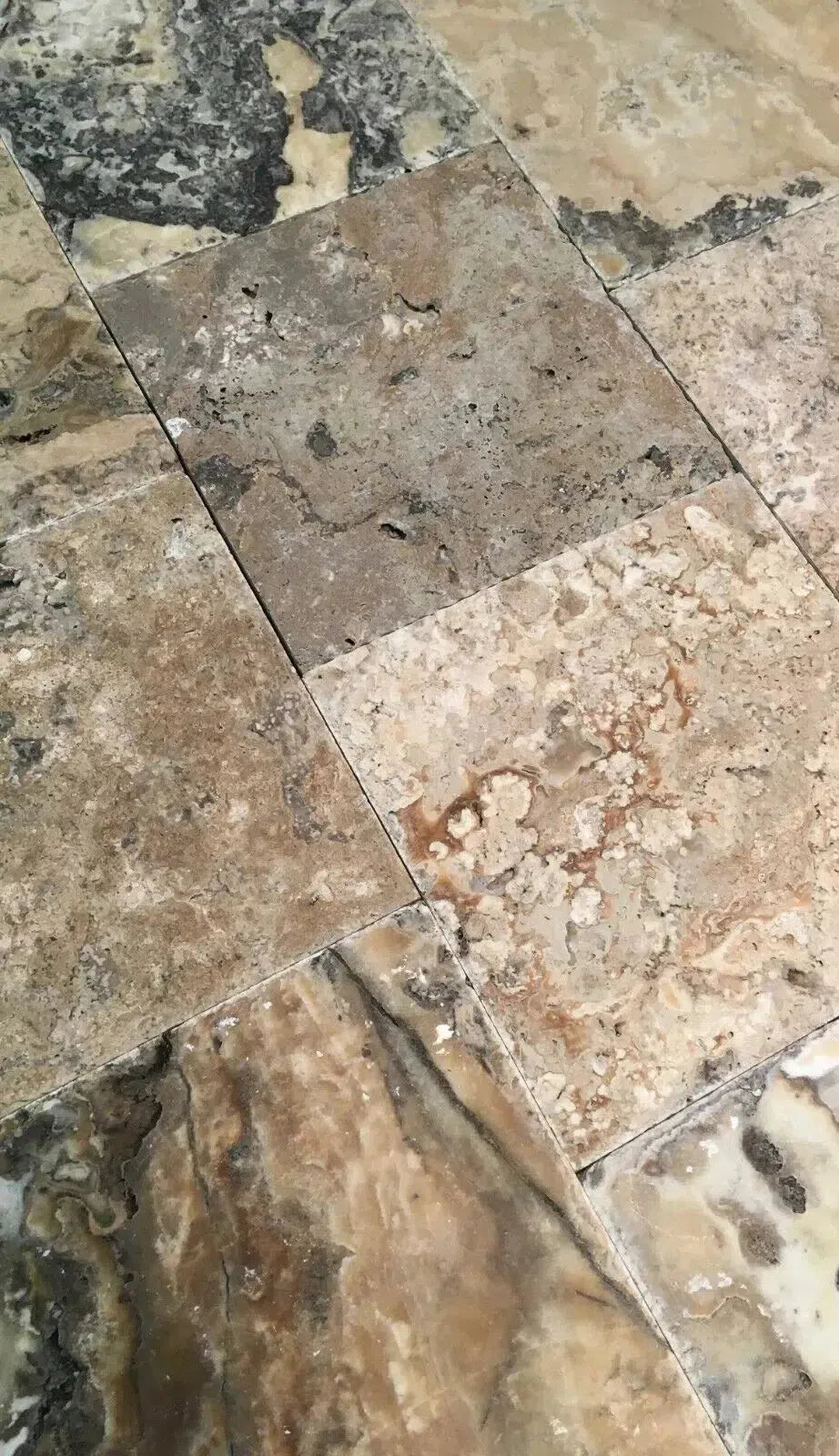

Scabos Travertine

Scabos Travertine

Sky Blue | Azul Cielo Marble

Sky Blue | Azul Cielo Marble

Silver Travertine

Silver Travertine

Snow White (Afyon White) Marble

Snow White (Afyon White) Marble

Spanish Mix Marble

Spanish Mix Marble

Statuary - Statuario White (Italian) Marble

Statuary - Statuario White (Italian) Marble

Thassos White (Greek) Marble

Thassos White (Greek) Marble

Tundra Gray (Atlantic Gray) Marble

Tundra Gray (Atlantic Gray) Marble

Valencia Travertine

Valencia Travertine

Valerenga Travertine

Valerenga Travertine

Walnut Travertine

Walnut Travertine

White Onyx Marble

White Onyx Marble

White Pearl/Botticino Beiege Marble

White Pearl/Botticino Beiege Marble

Shop By Type

Shop By Type

Shop By Finish

Shop By Finish

Accessories

Accessories

Clearance

Clearance

Best Selling Marble Collections

Best Selling Marble Collections

Arabescato Corchia

Arabescato Corchia Bardiglio

Bardiglio Bianco Dolomite

Bianco Dolomite  Carrara White

Carrara White  Calacatta Gold

Calacatta Gold Crema Marfil

Crema Marfil Emperador Dark

Emperador Dark Nero Marquina

Nero Marquina Thassos White

Thassos White Best Selling Travertine Collections

Best Selling Travertine Collections

Ivory Travertine

Ivory Travertine Noce Travertine

Noce Travertine Exotic Noce Travertine

Exotic Noce Travertine Scabos | Autumn Leaves Travertine

Scabos | Autumn Leaves Travertine Silver Travertine

Silver Travertine Exotic Travertine

Exotic Travertine Checkerboard

Checkerboard

Patterned Tile

Patterned Tile

Shop By Material

Shop By Material

Travertine

Travertine Marble

Marble Limestone

Limestone Soap Stone

Soap Stone Quartz

Quartz Granite

Granite Shop By Name

Shop By Name

Absolute Black Granite

Absolute Black Granite Atlantic Gray Marble

Atlantic Gray Marble Antico Onyx Travertine

Antico Onyx Travertine Bianco Congelato Dolomite

Bianco Congelato Dolomite Bianco Venatino (Bianco Mare) Marble

Bianco Venatino (Bianco Mare) Marble Calacatta Oliva Marble

Calacatta Oliva Marble Cappuccino Marble

Cappuccino Marble Custom-Made Mosaic

Custom-Made Mosaic Diano Royal (Queen Beige) Marble

Diano Royal (Queen Beige) Marble Durango Cream Traverine

Durango Cream Traverine Emperador Light Marble

Emperador Light Marble Empress Green Marble

Empress Green Marble Gold/Yellow Travertine

Gold/Yellow Travertine Green Onyx Marble

Green Onyx Marble Haisa Light (White Wood) Limestone

Haisa Light (White Wood) Limestone Honey Onyx Marble

Honey Onyx Marble La Travonya Travertine

La Travonya Travertine Malibu Travertine

Malibu Travertine Ming Green Marble

Ming Green Marble Mink (Equator) Marble

Mink (Equator) Marble Mixed (Ivory-Noce-Gold) Travertine

Mixed (Ivory-Noce-Gold) Travertine Oriental White Marble

Oriental White Marble Pierre Bleue (Pierre Blue) Marble

Pierre Bleue (Pierre Blue) Marble Philadelphia Travertine

Philadelphia Travertine Rosso Levanto Marble

Rosso Levanto Marble Rojo Alicante Marble

Rojo Alicante Marble Sky Blue | Azul Cielo Marble

Sky Blue | Azul Cielo Marble Snow White (Afyon White) Marble

Snow White (Afyon White) Marble Spanish Mix Marble

Spanish Mix Marble Statuary - Statuario White (Italian) Marble

Statuary - Statuario White (Italian) Marble Tundra Gray (Atlantic Gray) Marble

Tundra Gray (Atlantic Gray) Marble Valencia Travertine

Valencia Travertine Valerenga Travertine

Valerenga Travertine Walnut Travertine

Walnut Travertine White Onyx Marble

White Onyx Marble White Pearl/Botticino Beiege Marble

White Pearl/Botticino Beiege Marble Shop By Type

Shop By Type

Marble Tiles

Marble Tiles Marble Mosaic

Marble Mosaic Travertine Tiles

Travertine Tiles Travertine Mosaic

Travertine Mosaic 4 pcs Versailles Pattern / French Pattern Set

4 pcs Versailles Pattern / French Pattern Set Molding/Trim

Molding/Trim Border/Listello

Border/Listello Ledger-Panel

Ledger-Panel Checkerboard

Checkerboard Patterned Tile Collection

Patterned Tile Collection  Shop By Finish

Shop By Finish

Polished

Polished Honed

Honed Brushed

Brushed Split Face

Split Face Textured

Textured Tumbled

Tumbled Accessories

Accessories

Wall Plate / Switch Plate

Wall Plate / Switch Plate Shampoo Niche

Shampoo Niche Corner Shelf

Corner Shelf Clearance

Clearance